The Pipe Stretcher Extender DIY

I call this one the Pipe Stretcher. It is a combination of the best elements of what I have built in the past combined with improvements that I felt some of my other designs where lacking. I worked on it with the mindset of it being the last design I may ever make, so it probably is my swan song in the DIY extender game, as I have reached the goals I had hoped to for length and just don’t PE for length any longer. In a nutshell, this is my best attempt to design a easy to build a quality extender from materials you can find at most home building stores. I’ve put a lot of work into documenting the creation process with words as well as pictures because I do not know how quickly I will be able to respond to individual questions. Life has been a struggle lately… but I digress. To the Pipe Stretcher!

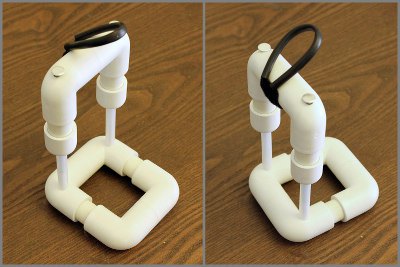

It makes use of a “quick noose” system that I have used in past designs. Yes it’s a noose, but it’s not a traditional noose, don’t worry, we will get in to that later. Unlike commercial extenders, this extender is not intended in any way to be hidden beneath clothing. That is for two reasons, one, I believe PE should be closely monitored at all times and secondly, due to the do it yourself nature of the project, easy to find and easy to build with materials can’t compete with custom molded plastic parts for size resulting in a larger end result. That, and nothing in my wardrobe could conceal even the smallest sized extender (except for this) so I scratched that off the list of things to worry about years ago.

Below is the construction tutorial, followed by the calibration, sizing and use of the device. Sorry, I do not have a budget price of what it will cost since I had a lot of the materials around from other projects but I purchased everything I used from the Home Depot, and most of the materials are found in the plumbing section.

The biggest improvements from previous designs are:

- The springs have been completely hidden.

- The noose more easily removes/attaches for initial sizing, cleaning, or replacement.

- Wider, more comfortable base.

- The base is now made from easier to find fittings.

- The alternate head configuration allows for a much greater range of sizes.

- Looks cooler.

Look close at the plans and images, they probably describe things better than my words ever could. Good luck! :)

(9.9 KB, 2773 views)

(103.1 KB, 1807 views)

(67.7 KB, 2878 views)

Keep an open mind and a closed wallet... unless it\'s open to making a donation!

Last edited by memento : 09-30-2014 at .